Sectors

- Mechanical

-

Oil & gas

- PED inspections and certifications

- inspections & expediting

- Drawings, calculations and mechanical design of pressure equipment and heat exchangers

- Iso 9001:2015 consulting services

- Type 3.2 requalifications of materials

- Plastic welder qualification

- Welder and braze operator qualification

- NDT operator certification (non-destructive testing)

- Thickness measurements

- Writing of technical dossiers in compliance with ped (2014/68/UE directive)

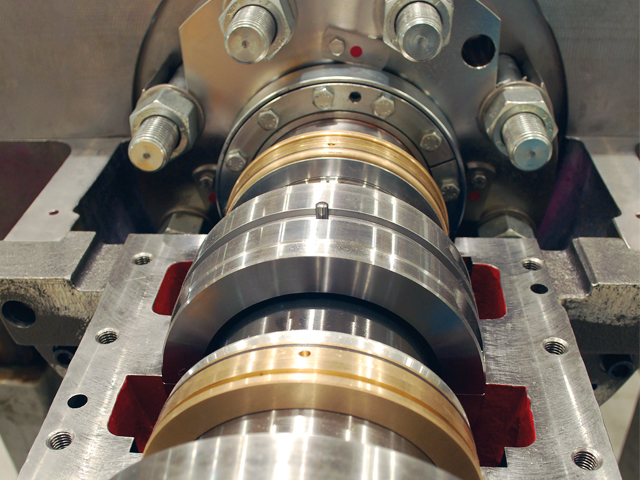

- Non destructive testing (NDT)

- Welding and welder qualification

- Energy and waste to energy

- Cement

- Aluminium processing

- Steelworks and foundries

- Chemical industry

- Pharmaceutical industry

- Food production and agro-chemical industry

- Non ferrous metals

- Water treatment

- Paper mills

- Glass and ceramics industry

- Wood industry

We provide the following services for the Oil & Gas sector:

- INSPECTION SERVICES

- COMPLETE INSPECTION SERVICES

Pre-inspection meeting, intermediate inspections, final inspections and review of supplier’s documentation in regard to the order to ensure product conformity throughout the entire manufacturing and production process. - PARTIAL INSPECTION SERVICES

This type of inspection includes a certain number of intermediate inspections and a final inspection. The services are performed either on a sample or on a spot basis, as defined by the customer. - FINAL INSPECTION SERVICES

At the end of the manufacturing process, a basic inspection service is usually included to ensure product compliance prior to shipment. - ONGOING INSPECTION SERVICES

Activities usually performed each time a customer requests an inspector to visit a particular manufacturer on a continuous basis over a certain period of time. These services monitor the entire production process and verify all the activities subject to inspection as defined by the customer.

- COMPLETE INSPECTION SERVICES

- SITE INSPECTION

- SEMCO offers on-site inspection services to ensure compliance with design requirements, codes, standards and specifications as well as environmental and health & safety regulations.

The aim is to minimise risk, reduce breakdowns, minimise operating costs, ensure integrity and extend the lifecycle of operations.

- SEMCO offers on-site inspection services to ensure compliance with design requirements, codes, standards and specifications as well as environmental and health & safety regulations.

- PIPING INSPECTIONS

- SEMCO is one of the few companies able to provide pipe monitoring services on any circular product and at any distribution point. Such services are available on an ad hoc basis, or on shift basis, as required by customers.

- INTEGRATED INSPECTION AND EXPEDITING SERVICES

- Expediters have different qualities, characteristics, skills and expertise and, therefore, these services must be provided by different professionals or individuals.

For those few cases when demanding tasks require the use of a single professional capable of performing both types of activities, SEMCO has selected a small pool of qualified technicians to address such challenges and meet customer needs and expectations.

Integrated inspection and expediting services are available on request, also at short notice.

- Expediters have different qualities, characteristics, skills and expertise and, therefore, these services must be provided by different professionals or individuals.

- PROJECT COORDINATION

- As from the start date of the assignment, the project coordinator is fully involved in order to define with the customer: the level of services required; the instructions for the field personnel; the provision of information, documentation and instructions to the team with regard to the assigned activities. All project coordinators have been trained in the project management philosophy with a proactive attitude to problem solving.

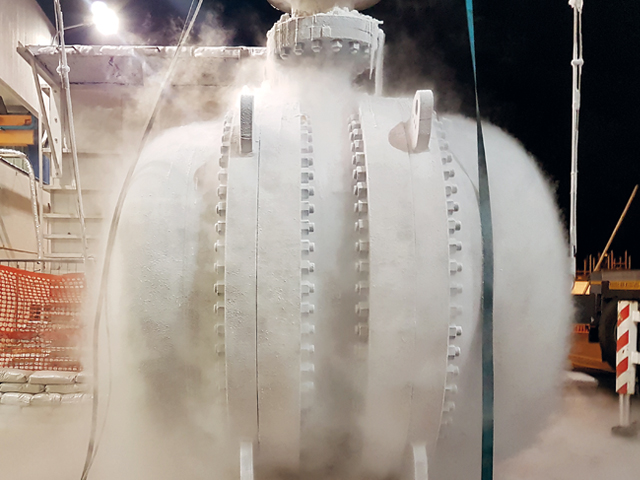

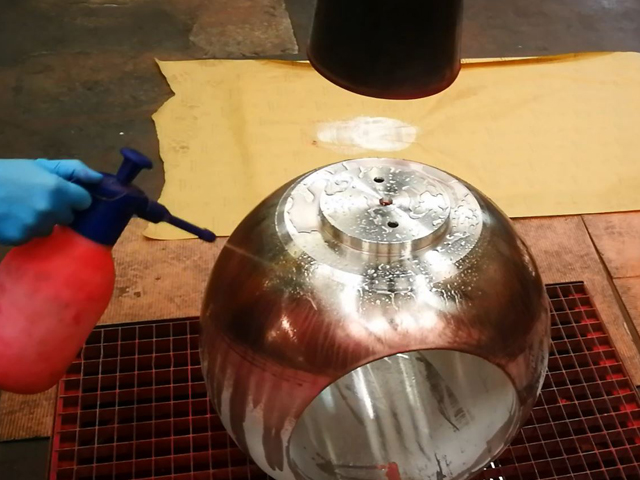

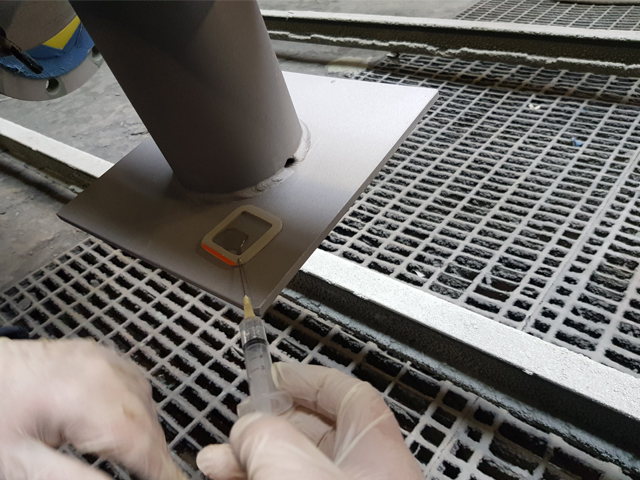

- ELIMINATION OF LEAKS WITH SYSTEMS IN OPERATION

- The service provided by SEMCO and referred to as “Elimination of Leaks with Systems in Operation” was introduced at the end of 2010 to respond to our customers’ need to guarantee the running of their plants while ensuring both safety and productivity.

We carry out, autonomously, the dimensional survey, the design and subsequent construction of the components suitable for the elimination of leaks.

With cutting-edge technology, we guarantee our customers temporary repairs of pipes and joints with pressures up to 300 bar and temperatures ranging from - 50 to + 750°C through the injection of thermosetting sealing compounds.

Moreover, SEMCO provides the customer with the necessary documentation for the relevant supervisory authorities, from measurements, which are part of the investigation phase, to intervention procedures.

SEMCO is able to give the customer a complete service from the dimensional survey to the submission of the PED temporary repair file to the competent bodies.

- The service provided by SEMCO and referred to as “Elimination of Leaks with Systems in Operation” was introduced at the end of 2010 to respond to our customers’ need to guarantee the running of their plants while ensuring both safety and productivity.

- TRAINING

- At SEMCO, we employ highly qualified and extremely competent inspectors with multidisciplinary skills including planning, manufacturing, installation, metallurgy, mechanical and electrical technology, welding, non-destructive testing, painting, corrosion, quality control and quality certifications.

SEMCO is committed to the continuous training of the personnel employed, to ensure all staff are up to date about the latest inspection processes, technologies and methodologies. The training provided includes: Non- Destructive Testing, Metallurgy, Welding, HSE Painting, Corrosion, and QA Auditors. Training plays a key role in ensuring that any organisation has the skills and competency needed to meet today's challenges. SEMCO offers cost-effective training solutions, designed to meet the highest expectations. All courses are designed to minimise training expenses by providing customised programmes that result in the accelerated development of talented professionals. SEMCO courses adopt the latest educational methods and can be held at our premises or at clients' premises. They are conducted by highly experienced and qualified training personnel.

NDT Inspector level III (SNT-TC-1A & ISO 9712) Welding Inspector Auditor of Management System Expediting Coating / Painting Inspector.

- At SEMCO, we employ highly qualified and extremely competent inspectors with multidisciplinary skills including planning, manufacturing, installation, metallurgy, mechanical and electrical technology, welding, non-destructive testing, painting, corrosion, quality control and quality certifications.

- REPORTING

- The report must faithfully provide complete information on the precise inspection activities performed, so it must be detailed and accurate. Digital images are also provided to improve the accuracy of the report content. The timely submission of reports is a crucial element in this process, which is why both our inspectors and project coordinators have been required to complete the process as quickly as possible.

- EXPEDITING

- DESK EXPEDITING SERVICES

For low criticality or non-strategic supplies. They provide general information with regard to the submission of the required documentation, placing of secondary orders, overall manufacturing progress and deliveries concerning a specific supply order. These services are generally provided at specific work stages or according to a timetable established by customers or recommended by the supplier.

The effectiveness of desk expediting services is optimised when performed jointly with field monitoring visits. - FIELD EXPEDITING SERVICES

All stages of the engineering, procurement, manufacturing and delivery processes are carried out promptly by suppliers in accordance with a known, agreed and reliable production schedule. Field expediting services are generally performed at the main supplier’s site, or at any sub-suppliers’ sites, to achieve specific objectives or according to a timetable established by customers or recommended by field operators. - FULL-TIME EXPEDITING SERVICES

Services required when an operator is requested to visit a specific supplier full-time for a given period of time. It allows our technicians to monitor all production processes and ensure compliance with scheduled delivery dates.

- DESK EXPEDITING SERVICES

- QUALITY CERTIFICATION

- PROCESS EVALUATION

SEMCO is able to conduct evaluation and audit visits to support customers in the verification of the organisation, management system, infrastructure, resources, production capacity and operational control of existing or new potential suppliers. The services provided include:- Evaluation of legal and financial status

- Management structure

- Company capabilities (sales, engineering, procurement, production processes, quality control, administration, logistics, after-sales, etc.)

- Analysis of supplier’s current and future workload

- Availability and condition of machines, equipment and tools

- Human resources and skills

- Reference lists / supplier experience

- Supplier qualifications/approvals

- Quality control system

- Quality management system and procedures

- Safety and environmental management system and procedures

- SUPPLIER’S QHSE MANAGEMENT SYSTEM

SEMCO is able to conduct ad hoc audits to verify whether the Quality and HSE management systems of any supplier, based on UNI EN ISO 9001, UNI EN ISO 14001, and UNI EN ISO 45001 standards, are properly implemented, maintained and updated.

Supplier audits are performed by certified auditors.

- PROCESS EVALUATION

- PROJECT MANAGEMENT

- VENDOR’S DOCUMENTATION EVALUATION

Independent review based on applicable customer requirements, codes, standards and specifications. This is associated with most products obtained from suppliers in our sectors.

The assessment will confirm whether a particular document issued by a particular manufacturer complies with the established requirements. This type of work can range from a simple evaluation of a particular document to a full approval process that includes issuing and updating a register of supplier documents.

Documents to be supplied: Inspection procedures within the inspection programme and tests (Hydro test, visual and dimensional test, functional test, performance test, execution test, etc.); NDT procedures (PT, MT, UT, RT, LT, etc.); Welding book (WPS , PQR, welding map); Surface preparation and painting procedures; Packaging procedures; Storage and preservation procedures; Manufacturer data books; Test certificates. - PROJECT OUTSOURCING & STAFFING

Thanks to its network of professionals and specialists, SEMCO offers rapid responses, flexibility, quality, effectiveness and client-oriented services at all stages of project execution.

The personnel dedicated to the project that SEMCO can provide include: project management staff, quality control project coordinators, project engineers (all disciplines), project inspectors and project procurement expediters, project material managers, project cost controllers, project document controllers, project welding specialists, project NDT specialists, data entry, and secretarial staff.

- VENDOR’S DOCUMENTATION EVALUATION

_b863c87c46.jpg)

_af43c15e85.jpg)

check_da3da09b35.jpg)

_fe4b7a56ed.jpg)

_7cb39c1b65.jpg)

_9126c49ac7.jpg)