Servizi

- PED inspections and certifications

- inspections & expediting

- Drawings, calculations and mechanical design of pressure equipment and heat exchangers

- Iso 9001:2015 consulting services

- Type 3.2 requalifications of materials

- Plastic welder qualification

- Welder and braze operator qualification

- NDT operator certification (non-destructive testing)

- Thickness measurements

- Writing of technical dossiers in compliance with ped (2014/68/UE directive)

- Non destructive testing (NDT)

- Refrigeration

- Welding and welder qualification

- Filtration

- Brazing and brazer qualification

- Training

- Fascicolo tecnico PED

- Controlli decennali obbligatori sulle attrezzature a pressione

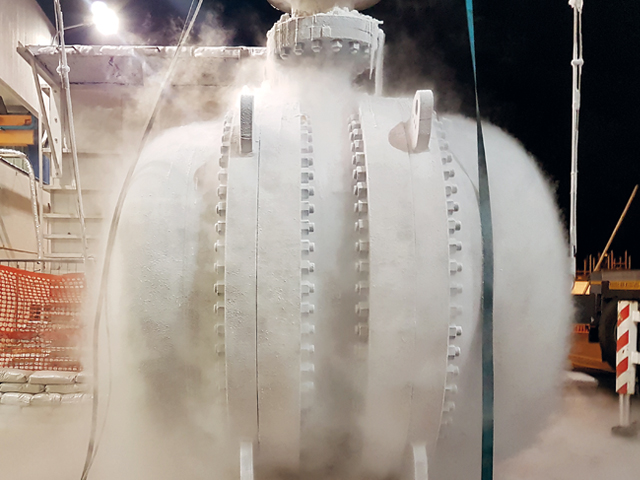

Non-destructive tests (NDT) are testing techniques, performed through non-invasive methods - therefore without altering the geometry and quality characteristics and the structural integrity of the material, or rather, tests aimed at detecting discontinuity or lack of homogeneity - without affecting the object’s ability to fulfil its intended function.

Non-destructive tests comprise:

- “Volumetric” testing (RT Radiographic testing; UT Ultrasonic Testing): they allow testing inside the piece.

- “Surface” testing (PT and LPI - Liquid Penetrant testing and inspection; MT and MPI - Magnetic particle testing and inspection): they allow surface or subsurface testing.

- Radiographic testing: a method which uses X-rays or Gamma rays to produce radiographic images on a film to be read

- Ultrasonic testing (UT): a method for the propagation of ultrasound waves, generated inside a component, using a reception and amplification device; the waves are displayed on a screen that records their behaviour inside the piece.

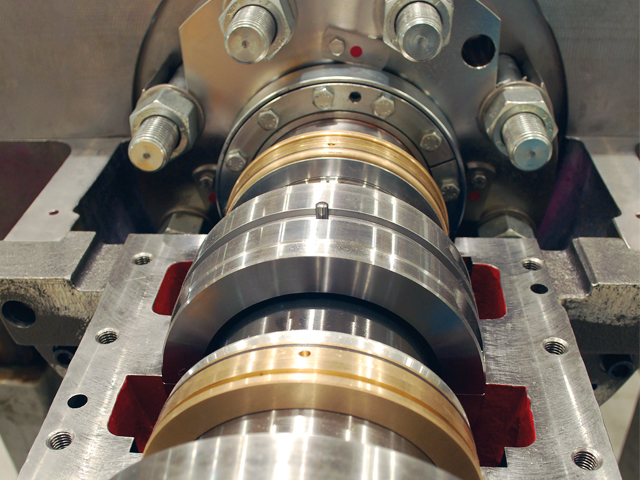

- Magnetic Particle Testing (MT): a method that can be performed on ferromagnetic materials, based on inducing a magnetic field on the surface of the piece under examination; any indications present produce a variation in the flow lines of the field generated and visible by means of special metal powders. They can be performed with dry, wet and fluorescent powders.

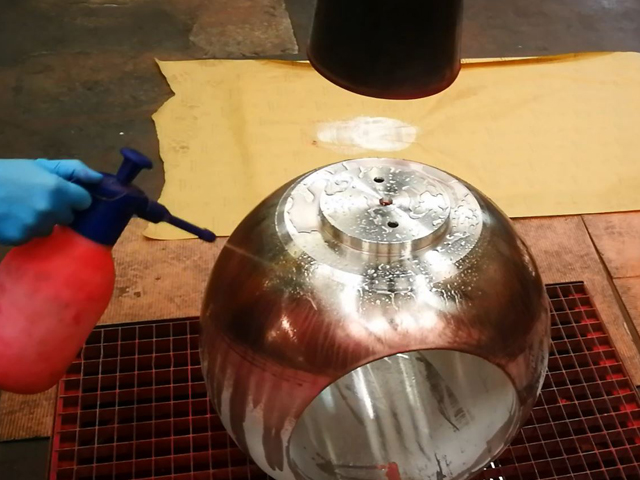

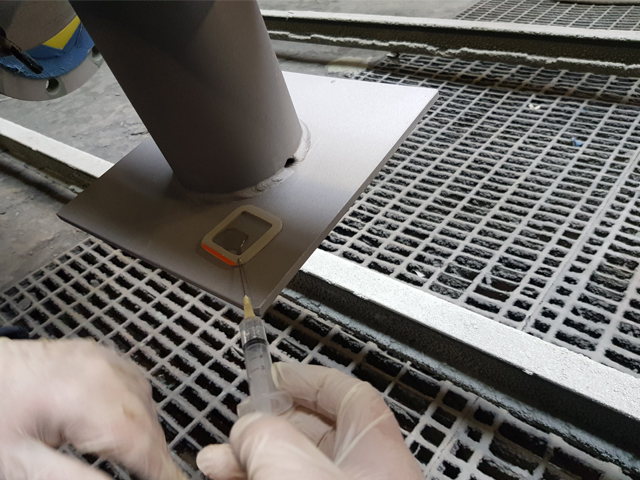

- Liquid Penetrant Testing (PT): a method based on the capillary action of the penetrant. The test result is detected through colour contrast.

The technical personnel that read and interpret the test results are certified for Level II UNI EN ISO 9712 (ex UNI EN 473) and SNT-TC-1A.

_b863c87c46.jpg)

_af43c15e85.jpg)

check_da3da09b35.jpg)

_fe4b7a56ed.jpg)

_7cb39c1b65.jpg)

_9126c49ac7.jpg)