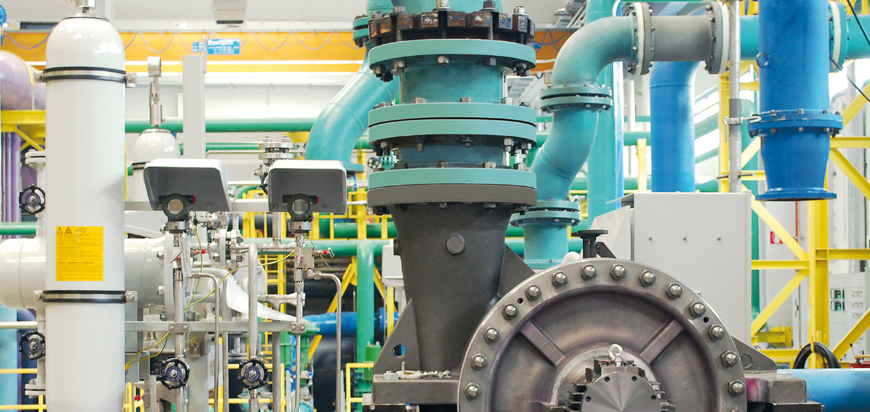

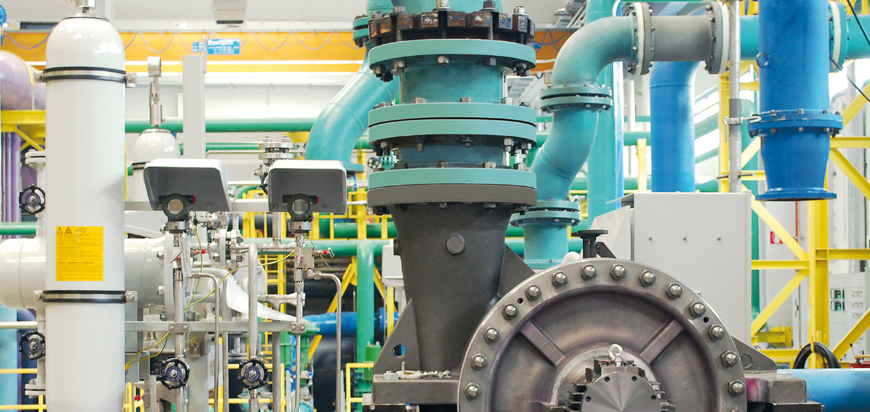

- Per le industrie metalmeccaniche che operano nel Chemical & Petrochemical, Power Generation, Offshore & Subsea.

- Ispezioni e certificazioni on site di prodotti e processi.

I nostri professionisti sono al tuo servizio per ispezioni industriali, ottimizzazione dei processi, audit tecnici, revisione e certificazione di macchinari industriali e processi nei settori petrolchimico (Oli & Gas), refrigerazione e filtrazione industriale. Garantiamo il massimo livello di efficienza e tempestività di ogni nostro intervento.

approfondisci

Paesi

Settori

Business Unit

Commesse / Anno

Lunga esperienza, competenza tecnica ed un approccio fortemente orientato al cliente, ci permettono di fornire soluzioni personalizzate innovative ed efficienti per qualsiasi esigenza.

approfondisci

La nostra rete internazionale di tecnici ed ispettori industriali è in grado di seguire progetti, anche di ampia complessità e portata, in qualsiasi parte del mondo. Con un network professionale, diffuso capillarmente in ogni continente, garantiamo un servizio altamente qualificato, un’assistenza costante e un intervento in tempi molto rapidi.

Con piccoli e grandi clienti, in Italia e all’estero

Pieno rispetto delle normative e codici di calcolo internazionali

I nostri tecnici sono in possesso delle qualifiche e autorizzazioni necessarie per soddisfare le esigenze di qualsiasi player in ogni settore industriale

CSIM, aumento di capitale e nuovo socio industriale

Milano, 2 maggio 2022 – L’Assemblea straordinaria dei soci di CSIM Srl, società leader specializzata nella consulenza, progettazione, project management e formazione per il settore della refrigerazione e della climatizzazione, ha deliberato un aumento del proprio...

Ho trovato un grande valore nel lavorare con SEMCO. Sono professionisti affidabili con soluzioni intelligenti e una vasta rete di contatti in grado di supportare ogni esigenza. La progettazione e l’engineering necessitano di un team affidabile e capace. Abbiamo avuto un’entusiasmante esperienza con SEMCO.

With SEMCO GROUP high professionality and flexibility we found the Partner to guarantee quality and delivery of the Project.